Introduction

As the world faces a climate emergency, industries are racing to find sustainable alternatives to synthetic and non-renewable materials. One of the most overlooked yet powerful solutions lies in one of nature’s oldest resources: wool.

Wool has insulated humans for thousands of years — keeping us warm, absorbing moisture, and maintaining comfort in extreme conditions. But today, innovators are rediscovering wool’s potential far beyond fashion.

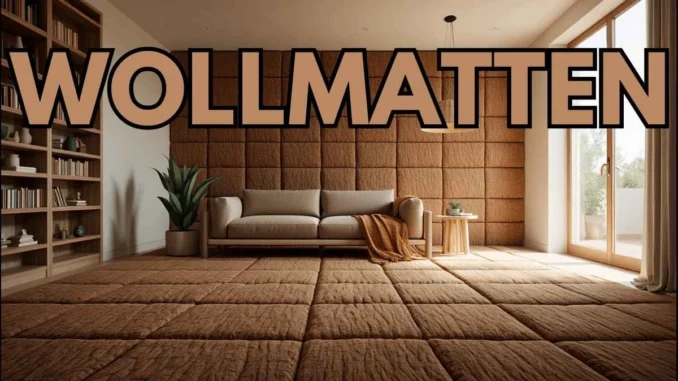

At the forefront of this movement stands Wollmatten, a pioneering company dedicated to producing eco-friendly wool mats for insulation, horticulture, and environmental engineering. Through a blend of traditional craftsmanship and cutting-edge technology, Wollmatten is redefining how natural fibers can shape a sustainable future.

The Origins of Wollmatten

A Mission Born from the Circular Economy

Wollmatten was founded on a simple but powerful principle: waste is a resource waiting to be reimagined.

Every year, the global textile industry discards millions of tons of wool that doesn’t meet fashion-grade standards. Instead of allowing this valuable natural material to go to waste, Wollmatten’s founders — a team of environmental engineers, farmers, and material scientists — envisioned a closed-loop system that transforms excess wool into functional, high-performance products.

The company’s mission is to create a circular wool economy, turning agricultural byproducts into sustainable materials that serve construction, horticulture, and ecological restoration.

The Science Behind Woolmatten

Wool: Nature’s Smart Fiber

Before understanding Wollmatten’s technology, it’s important to appreciate wool’s natural advantages. Unlike synthetic materials, wool is biodegradable, renewable, and thermoregulating. It can absorb up to 30% of its weight in moisture without feeling damp, and it naturally resists fire, mold, and bacteria.

Each wool fiber is a complex protein structure — a natural composite of keratin surrounded by microscopic scales that trap air. This gives wool remarkable insulating properties and makes it an excellent candidate for eco-engineering applications.

Wollmatten’s Product Ecosystem

Wollmatten has diversified its product line into three major categories, each addressing a unique sustainability challenge: insulation, horticulture, and ecological restoration.

1. Wollmatten EcoTherm™ – Natural Building Insulation

Traditional insulation materials — such as fiberglass, mineral wool, or polyurethane foam — are energy-intensive to produce and often emit volatile organic compounds (VOCs). Wollmatten offers a clean alternative: EcoTherm Wool Mats.

Features and Benefits

- Thermal Performance: Comparable to conventional insulation, with an R-value of 3.8–4.0 per inch.

- Moisture Regulation: Absorbs humidity in winter and releases it in summer, preventing condensation and mold.

- Air Purification: Naturally binds indoor pollutants like formaldehyde.

- Acoustic Insulation: The dense fiber structure provides superior sound absorption for walls and floors.

Wollmatten’s insulation products are made using mechanical felting and needle-punching techniques, requiring no synthetic binders. The result is a flexible, durable mat that’s completely biodegradable at the end of its life cycle.

Applications

- Residential and commercial wall, floor, and roof insulation.

- Prefabricated eco-housing panels.

- Heritage building retrofits where breathable materials are essential.

2. Wollmatten AgroFleece™ – Sustainable Gardening and Agriculture

In agriculture, plastic-based mulch and geotextiles are a major environmental concern. They degrade into microplastics that pollute soil and waterways. Wollmatten’s AgroFleece mats offer a natural solution.

How It Works

The mats are laid directly on the soil surface, where they:

- Retain moisture and reduce evaporation.

- Suppress weed growth naturally, without herbicides.

- Gradually decompose, enriching the soil with nitrogen and trace elements.

Environmental Impact

Each AgroFleece mat replaces up to 10 square meters of plastic mulch, reducing CO₂ emissions by approximately 2.5 kg compared to synthetic alternatives.

Use Cases

- Organic farms and vineyards.

- Greenhouses and urban gardens.

- Tree planting projects in arid regions.

3. Wollmatten BioGeo™ – Erosion Control and Landscape Restoration

One of Wollmatten’s most innovative applications lies in environmental engineering. The company’s BioGeo wool mats are used for erosion control, riverbank stabilization, and reforestation projects.

Key Advantages

- The fibers’ structure helps anchor soil and prevent runoff.

- Wool’s ability to retain moisture promotes seed germination.

- As the mats biodegrade, they release nutrients that enhance vegetation growth.

In collaboration with European environmental agencies, Wollmatten’s BioGeo mats are being deployed in coastal dune restoration and mountain slope stabilization projects, replacing synthetic geotextiles that can persist in nature for decades.

Technology and Innovation

The Production Process

Wollmatten’s process combines traditional wool processing techniques with modern environmental engineering.

- Sourcing: Raw wool is collected from regional farms and shearing cooperatives.

- Cleaning: A low-water, biodegradable detergent system removes lanolin and dirt.

- Felting: The wool is carded and mechanically interlocked using pressure and vibration — no adhesives required.

- Customization: Thickness, density, and fiber composition are adjusted based on intended application (construction, agriculture, or ecology).

The result is a line of high-performance, 100% natural wool mats that outperform many synthetic counterparts in both durability and sustainability.

AI and Circular Design

Wollmatten integrates AI-driven data analytics into its operations to optimize sourcing and waste management.

The company’s software tracks wool supply across regions, forecasts demand, and ensures minimal transportation emissions — embodying the principles of smart sustainability.

Additionally, through partnerships with local textile recycling programs, Wollmatten can upcycle post-consumer wool garments into new mats, closing the loop completely.

Sustainability at the Core

Zero-Waste Philosophy

Every step of Wollmatten’s production chain is designed to minimize waste:

- Wool offcuts are reprocessed into new mats.

- Lanolin extracted during cleaning is repurposed for cosmetics and lubricants.

- Packaging is made from recycled paper and plant-based fibers.

Carbon and Energy Savings

Compared to traditional insulation manufacturing, Wollmatten’s process:

- Uses 75% less energy.

- Emits 60% fewer greenhouse gases.

- Avoids toxic chemicals entirely.

The company’s goal is to become carbon neutral by 2030, supported by renewable energy facilities at its main plant and ongoing lifecycle assessments to measure environmental performance.

Applications Across Industries

1. Green Construction

Architects and builders use Wollmatten products for eco-housing, passive buildings, and LEED-certified projects. The material’s breathability and comfort align with sustainable architecture principles.

2. Urban Greening

Wollmatten mats are used in green roofs, urban tree pits, and vertical gardens to enhance moisture retention and plant health while reducing heat island effects.

3. Environmental Restoration

Government and NGO projects employ Wollmatten mats in reforestation, wetland rehabilitation, and desert reclamation initiatives, where synthetic erosion controls are unsustainable.

Global Impact and Collaborations

Wollmatten has rapidly expanded across Europe, with operations in Germany, Austria, and the Nordic countries. The company collaborates with:

- Architectural institutes researching bio-based insulation.

- Agricultural universities developing biodegradable crop protection.

- Environmental NGOs restoring ecosystems using natural materials.

In 2025, Wollmatten plans to open its first North American production hub, supporting the growing demand for sustainable building materials in the U.S. and Canada.

Challenges and Future Goals

1. Consumer Awareness

Despite its advantages, natural wool materials remain underrepresented in mainstream construction and agriculture. Educating consumers and professionals about their benefits is key to growth.

2. Cost Competitiveness

Wool-based products are slightly more expensive than plastic alternatives. However, when lifecycle and disposal costs are considered, Wollmatten’s products are economically and ecologically superior.

3. Innovation Roadmap

Wollmatten is developing hybrid mats that blend wool with hemp or flax fibers to enhance tensile strength for heavy-duty engineering uses. Research is also underway on fireproofing treatments using natural minerals.

Conclusion

Wollmatten stands as a shining example of how ancient materials can power modern sustainability. By transforming surplus wool into high-performance mats, the company bridges traditional craftsmanship with next-generation environmental technology.

From homes and farms to mountains and coastlines, Wollmatten’s products are quietly revolutionizing industries — replacing pollution with regeneration and waste with circular innovation.

In a world urgently seeking climate solutions, Wollmatten reminds us that sometimes, the best technologies are the ones nature gave us long ago — we just needed to rediscover them.

Leave a Reply